The convenience brought by electricity believes that everyone can feel it more or less. The existence of electricity can not only satisfy the use of furniture in our daily life, but as an energy source, it can also provide power. This is due to the existence of the motor, through the use of commutators and other tools that are applied to physical principles, and finally provide power. However, some problems will inevitably occur during the use of the forklift motor commutator. Next, we will carry out relevant understanding in this regard.

Problems and solutions of motor commutator

1. The commutator is out of round or the rectifier sheet is uneven, the mica sheet is protruded from the surface of the rectifier, and the carbon brush jumps during operation. The armature should be removed for turning, and the mica between the rectifier sheets should be cut by 0.5 to 0.8 mm after turning. And when the generator is idling, use sandpaper to remove the burr of the commutator.

2. The armature winding is broken or the welding head between the armature winding and the rectifier is de-soldered, and the normal commutation is damaged during operation. Connect the broken wire or re-weld the de-soldered place.

3. The carbon brush is excessively worn, the brush holder spring is too soft, and the carbon brush pressure is not enough. It should be replaced with a new brush. During emergency repairs, a wooden block or paper can be placed on the rear to use the carbon brush pressure.

4. The carbon brush and the carbon frame are too tightly matched, which makes the contact between the brush and the commutator worse. It is better to use sandpaper to grind the small carbon brush slightly so that it can slide up and down in the brush frame without shaking.

5.The brush holder is loose and should be tightened.

The existence of the commutator problem will naturally affect the power supply, and people have a long history of using electricity, and the dependence is already very large, so when the commutator has a problem that affects work efficiency, you need to Promptly deal with. The above is the analysis and solution of common problems. As a manufacturer of forklift motor commutators, our company will continue to provide you with professional knowledge in this regard.

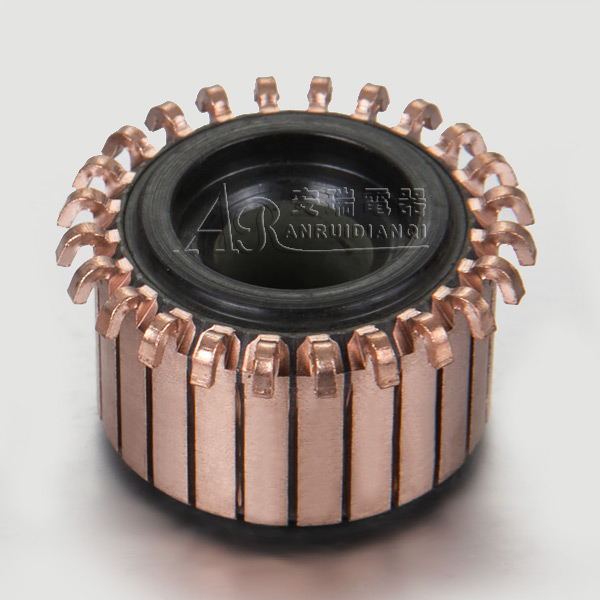

24 Segment Garden Tools Commutators

Overview

Place Of Origin:China(Mainland)

Brand Name:AR Commutator

Commutator:Commutator For Motor

Type:Commutator

Size:Customized

Delivery Time:30 Days For Commutator Mass Production

Packing:Cartons

Usage:Commutator For Power Tools

Supply Ability:1000000 Pieces/Mouth

Packing&delivery:Paper Cartons With Paiiets Customized

Port:Ningbo/Shanghai