How to maintain DC motor commutator

(1) Purge and wipe the commutator surface to ensure cleanliness.

(2) Establish a production process of reasonable distribution of motor load to ensure that a good film (also called oxide film) is established on the surface of the commutator. It is found that the surface condition of the commutator deteriorates and the spark is relatively large.

(3) Check whether the mica groove is clean, and the corners of the commutator should be smooth and free of burrs.

(4) Under the condition of ensuring the surface quality of the commutator, it is also necessary to carefully observe and monitor the commutation spark in daily operation. Under normal circumstances, point-like and granular sparks are sparsely and evenly distributed on most of them, which are normal commutation sparks. A sonic, fireball, or splash spark is a harmful spark. When ring fire sparks occur, the motor should not continue to run.

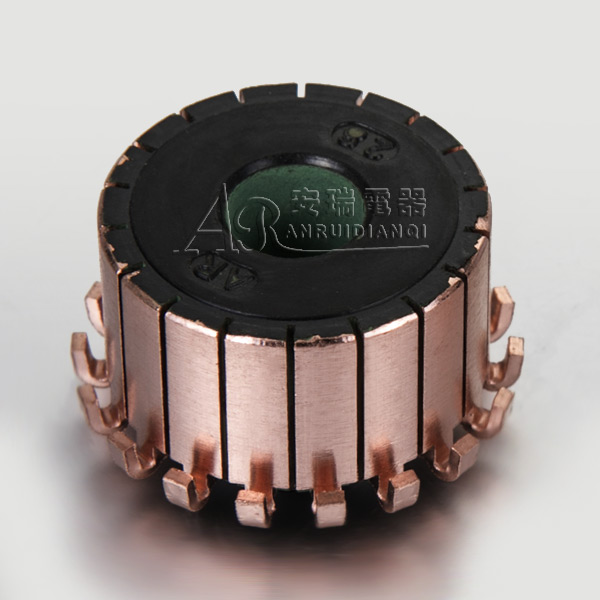

The motor commutator is a current commutator composed of commutator, mica, V-shaped insulating ring, pressure ring and fasteners on the DC rotor. The commutator, commonly known as the commutator. It is a part of the DC permanent magnet series motor in order to allow the motor to continue to rotate. The commutator includes: mechanical commutator, semi-plastic commutator, full plastic commutator. The principle is that when a current is passed, it will be rotated by attraction and repulsion under the action of a permanent magnet. When it turns and balances with the magnet, the originally energized line corresponds to the contact piece on the commutator. The brushes are separated, and the brushes are connected to the corresponding sets of contacts that meet the driving force, so that the DC motor rotates as it repeats. If there is no function of the commutator, the motor can only be locked within half a turn, and can only be used as an electric brake.