In the design of the diameter of the reversing equipment, the maximum speed limit of the contact between the reversing equipment and the carbon brushes must be considered first. The radius of the cylindrical reversing equipment must meet the contact radius, and the appropriate space for the carbon brushes must also be considered. The most important thing is to consider current density to the commutation device.

Generally, the current density of copper material is determined according to the allowable maximum temperature of the wire core, cooling conditions, and laying conditions. Generally, the current density of copper wire is 5~8A/mm2, and the current density of aluminum wire is 3~5A/mm2. Generally, the current density of copper wire is 5~8A/mm2, and the current density of aluminum wire is 3~5A/mm2. For example: the recommended value of the current density of the 2.5 mm2 BVV copper wire is 2.5×8A/mm2=20A The recommended value of the current density of the 4 mm2 BVV copper wire is 4×8A/mm2=32A.

|

Overview |

|

|

Place Of Origin |

China(Mainland) |

|

Brand Name |

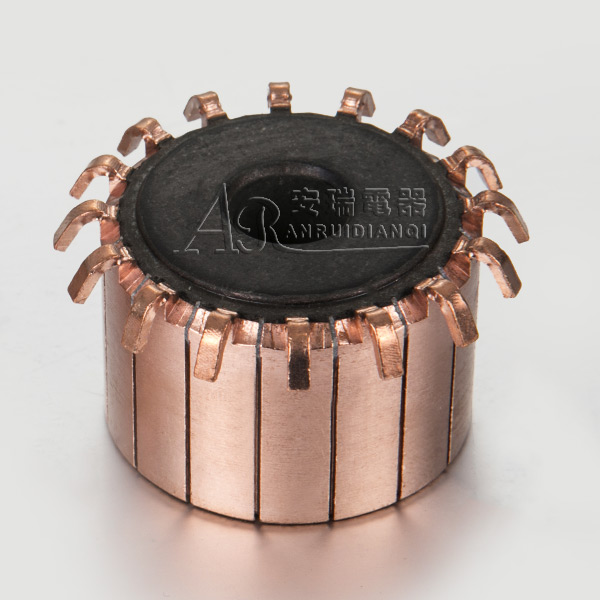

AR Commutator |

|

Commutator |

Commutator For Motor |

|

Type |

Commutator |

|

Size |

Customized |

|

Delivery Time |

30 Days For Commutator Mass Production |

|

Packing |

Cartons |

|

Usage |

Commutator For Power Tools |

|

Supply Ability |

1000000 Pieces/Mouth |

|

Packing&delivery |

Paper Cartons With Paiiets Customized |

|

Port |

Ningbo/Shanghai |

Therefore, if possible, to meet the requirements of the maximum current density between the carbon brush and the commutator, the minimum area of copper is as small as possible in the structure and manufacturing accuracy of the commutation device under the condition of the diameter of the commutation device; in order to To ensure the high quality and sufficient strength of the reversing equipment, the copper material used in the reversing equipment must have a certain hardness range. The general value is HB80-HB120, preferably in the middle section of HB95-HB105. Copper and a certain content of silver, this ensures that the reversing device has sufficient hardness even at extreme temperatures.