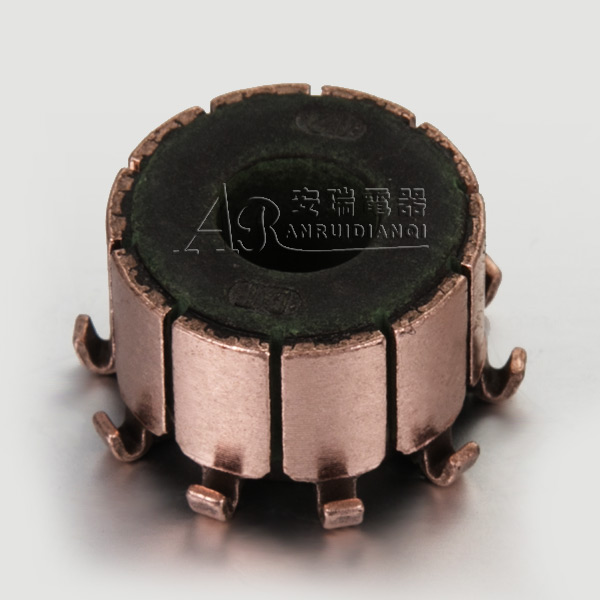

1. Commutator structure

The commutator is mainly composed of mica chips and commutator segments, and its structure is shown in Figure 2-26.

2. Overhaul of commutator common faults

The commutator is an important part of a DC motor. Due to its many parts and complicated structure, it is easy to malfunction during motor operation. The following describes the repair of common faults of the commutator.

The final overall forming of the commutator adopts a hot pressing process, in which the reversible sheet and the mica sheet are arranged in a cylindrical shape, and the shaping mold is placed, and then pressed into the pressing mold to put the plastic which weighs the weight; Commonly used phenolic glass fiber plastic, closed upper mold, pressed on a hot press, hot pressing temperature is 150 ~170 ° C, pressure is about 300 x 105 Pa (about 300kgf / cm2), according to the thickness of the commutator, in 5 ~ 15 It was formed in minutes and then post-cured at 130 ° C for 5 hours.

Another all-plastic commutator, the inter-chip insulation is a plastic that is integral with the housing. Most of the commutators are made into a hook shape, and the commutator material is processed by a copper tube. The tooth grooves are first milled at both ends of the copper tube, leaving the teeth to be bent, and the other milled teeth are bent inward. Form an angle of 30 ~ 45 ° with the inner wall of the copper tube, then put it into the stamper, add plastic hot sweat, press forming, then engrave the groove, and then mill the copper tube wall, which becomes a complete commutator. This structure is mostly used on small commutators, and has the advantages of material saving and simple process. In order to save copper and is more suitable for automated production, steel sheet material is used, which is rolled, punched, rounded and then compression molded. This process has been used in mass-produced all-plastic commutators.